Latest news

The bio-based biomass heat treatment team from the College of Material Science and Technology, Beijing Forestry University recently achieved significant advance in puffed bamboo and the regulation of its pore structure. Their research paper, titled "A facile method for constructing non-carbonised puffed bamboo with hierarchical pore structure based on self-exploding mechanism", has been published in Construction and Building Materials (IF=7.4).

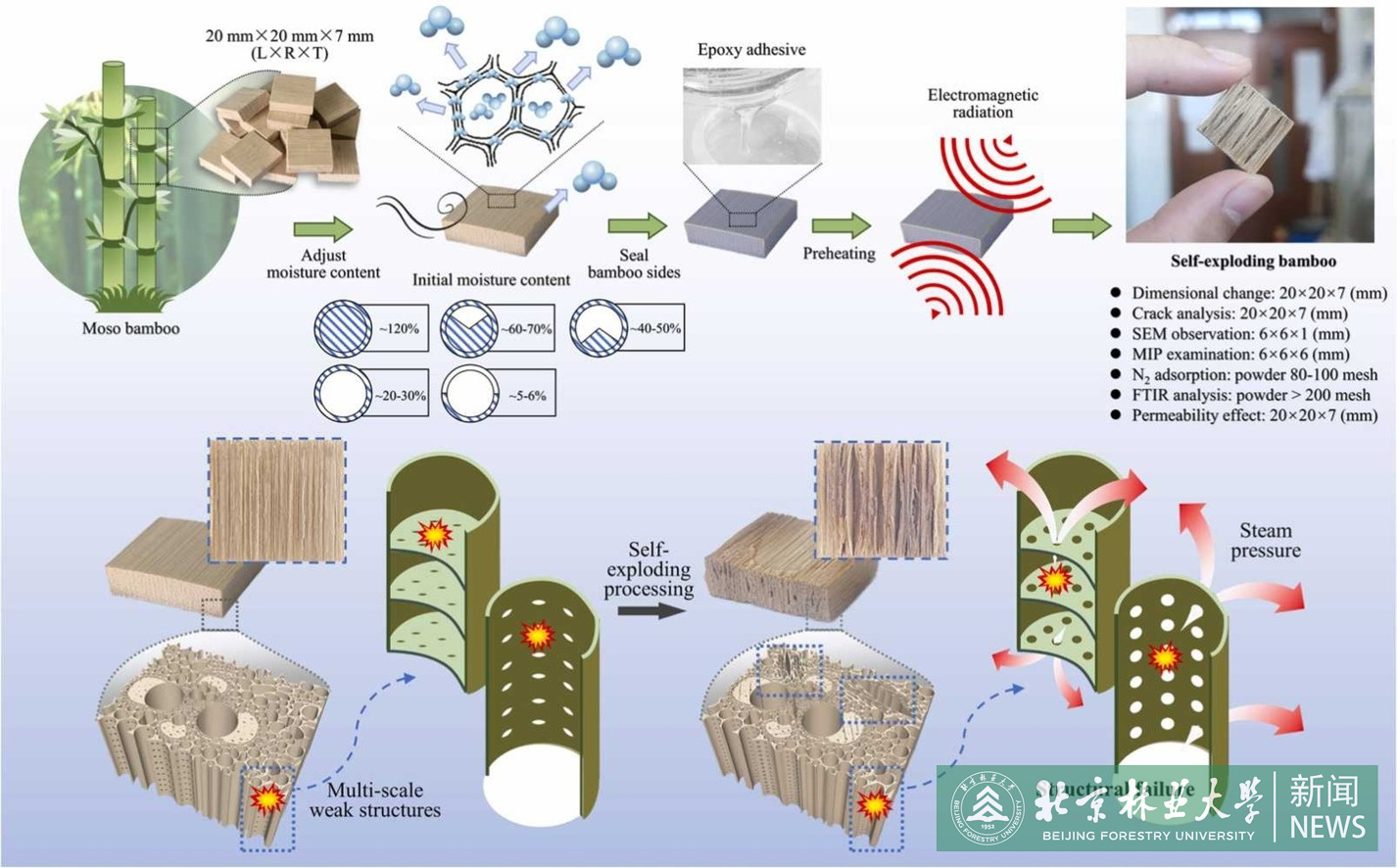

Bamboo as a porous biopolymer rich in modifiable functional groups has been considered as an ideal template for the synthesis of functional materials due to its skin-friendly and other properties. Limited by poor permeability, it is difficult to form uniform and deep fluid channels inside natural bamboo, which affects the development of further functionalized bamboo. Efficient and non-polluting electromagnetic radiation applied to bamboo is understood to remodel its internal structure. However, shrinkage and severe densification of the bamboo porous structure (a large volume reduction of 28.90%) was generally led by existing radiation treatments, and large amounts of energy consumption was caused by high level electromagnetic radiation. To enhance the impregnation capacity of bamboo while reducing volume collapse, and simultaneously mitigate carbon emissions pollution resulting from energy consumption, a facile and efficient low-level super high frequency electromagnetic radiation method was proposed. This method is employed to fabricate non-carbonized puffed bamboo with a unique hierarchical pore structure based on the self-exploding mechanism. The results showed that the volume expansion of puffed bamboo was as high as 14.75% compared to natural bamboo. Many macroscopic cracks and localized densification were created. The specific surface area was increased by 56.90% and the porosity was increased by 10.69%, of which the total pore volume of the micropores and the mesopores with diameters less than 50 nm increased by 30.43%. The puffed bamboo showed great fluid permeability. This approach allows the internal structure of bamboo to be remodeled so that it can be used as a template for porous biopolymers in a variety of applications such as structural materials. In addition, to further assess the general applicability of this puffed bamboo-based template, it was demonstrated that the dye adsorption can be sustained for 480 h, the weight percentage gain of metal impregnate was increased by 163.23%, and the weight percentage gain of resin impregnate was increased by 24.08%. The short growth cycle and renewable features of bamboo combined with a facile and efficient fabrication process make puffed bamboo a promising potential for more applications, such as building materials.

The first author of the paper is Zhang Tianfang, a doctoral candidate at the College of Materials Science and Technology with Professor Yi Songlin and Associate Professor He Zhengbin as the corresponding authors. Beijing Forestry University is the signature unit of the first author.

This work was supported by “Science Technology Department of Zhejiang Province (2022F1068-1)”, “National Key Research and Development Program of China (2023YFD2201402)”, “Fundamental Research Funds for the Central Universities (BLX202235)” and “Fundamental Research Funds for the Central Universities (BFUKF202315)”. We acknowledge Yongshun Feng for his support on the experimental setup and suggestions on the technological process design.Paper link: https://doi.org/10.1016/j.conbuildmat.2024.136049

Written by Zhang Tianfang, He Zhengbin

Translated and edited by Song He

Reviewed by Yu Yangyang