Latest news

Recently, Professor Xu Feng' s team from the College of Material Science and Technology achieved breakthroughs in developing lignin-based materials for 3D printing electrodes. Their research paper "Advanced MXene/Graphene Oxide/Lignosulfonate Inks for 3D Printing Thick Electrodes with Vertically Aligned Pores to Dually Boost Mass Loading and Areal Capacitance" was published in Advanced Functional Materiala (IF=18.5).

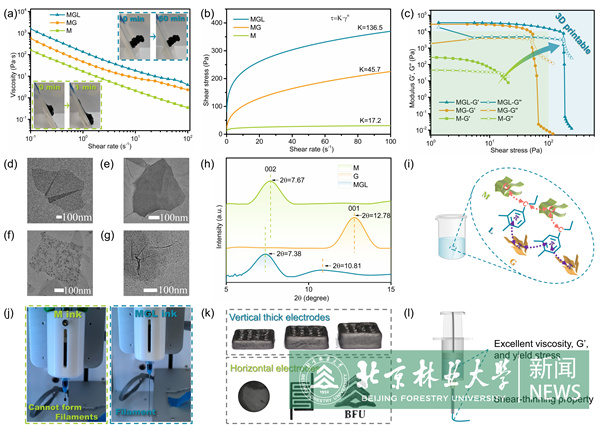

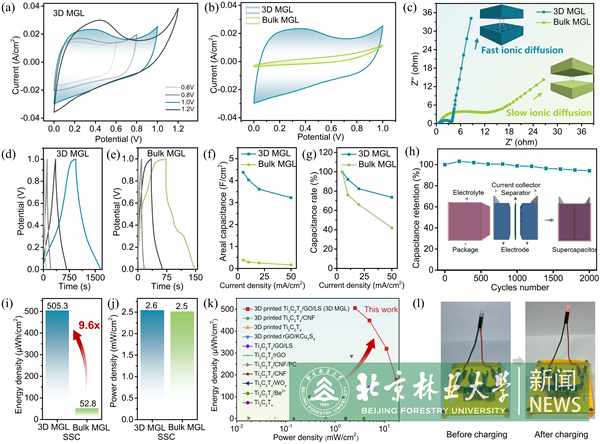

Direct ink writing 3D printing, using ink extrusion, promises to transform conventional 2D thin electrodes into 3D thick architectures for high-performance supercapacitors. However, formulating 3D printing inks and designing 3D architectures for electrodes remain challenges. In this work, a novel MXene/graphene oxide/lignosulfonate (MGL) ink with excellent rheological properties is developed for 3D printing MGL thick electrodes with vertically aligned architectures. The MGL ink exhibited excellent shear-thinning properties for smooth 3D printing and shape retention after printing. The 3D-printed MGL thick electrode, with a thickness of up to 4 mm, achieved a breakthrough mass loading of 72.1 mg cm−2, resulting in an extremely high areal capacitance of 8.6 F cm−2 that is 9.6 times greater than the value observed for the bulk MGL electrode (0.9 F cm−2). Additionally, supercapacitors using the 3D MGL electrode achieved an energy density of 505.3 µWh cm−2, significantly surpassing the value for bulk MGL electrode (52.8 µWh cm−2). This enhancement is attributed to the efficient design of the electrodes, where vertically aligned pores in the 3D MGL electrode enhanced ion transfer and reaction kinetics. This study demonstrates an innovative approach for formulating inks and provides guidance for designing 3D thick electrodes with rapid ion transport and excellent electrochemical performance.

Ye Haichuan, a Ph.D student from the College of Material Science and Technology, is the first author of the paper, with Associate Professor You Tingting and Professor Xu Feng serving as the co-corresponding authors.

This study was funded by the National Natural Science Foundation of China (NSFC) (grant number U22A20422, 22178028, and 22378025), the Programme of Introducing Talents of Discipline to Universities, Project 111 (grant number B21022), and 5·5 Engineering Research & Innovation Team Project of Beijing Forestry University (No: BLRC2023B01).

Paper link: https://doi.org/10.1002/adfm.202413343

Written by You Tingting, Ye Haichuan

Translated and edited by Song He

Reviewed by Yu Yangyang