Latest news

Recently, the biomass adhesive research team of the College of Material Science and Technology has made new progress in wood-based new materials, and ACS Nano (IF=17.1) ,a regional Top journal of the Chinese Academy of Sciences, published the reserach result entitled "Preparation of Strong and Thermally Conductive, Spider Silk-Inspired, Soybean Protein-Based Adhesive for Thermally Conductive Wood-Based Composites" .

The development of formaldehyde-free functional wood composite materials through the preparation of strong and multifunctional soybean protein adhesives to replace formaldehyde-based resins is an important research area.

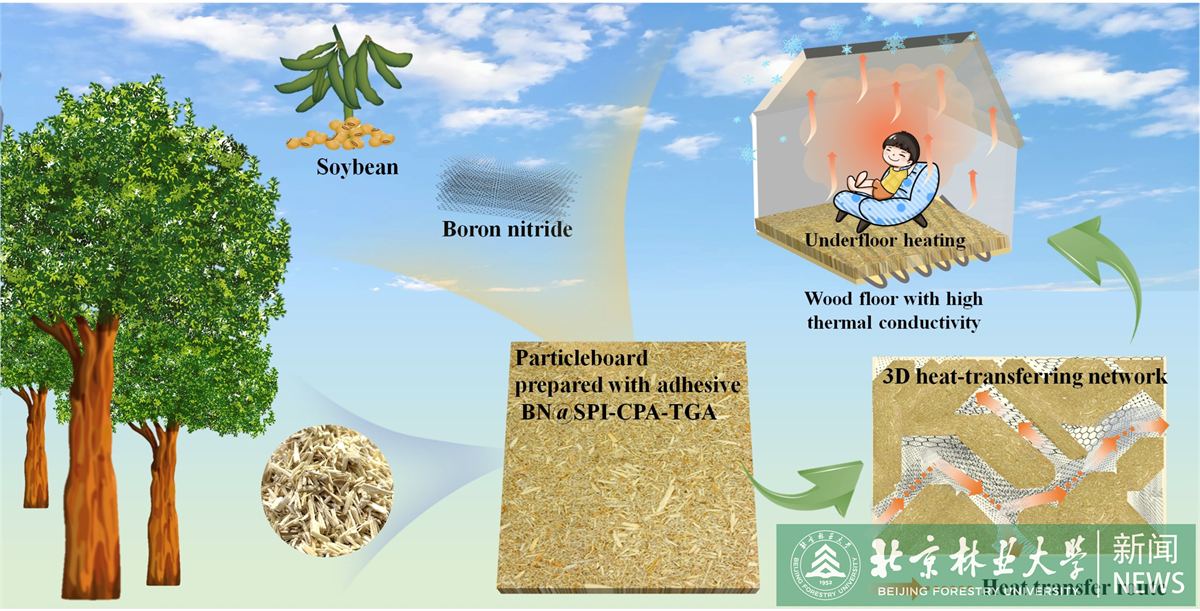

However, ensuring the bonding performance of soybean protein adhesive while simultaneously developing thermally conductive adhesive and its corresponding wood composites is challenging. Taking inspiration from the microphase separation structure of spider silk, boron nitride (BN) and soy protein isolate (SPI) were mixed by ball milling to obtain a BN@SPI matrix and combined with the self-synthesized hyperbranched reactive substrates as amorphous region reinforcer and cross-linker triglycidylamine to prepare strong and thermally conductive soybean protein adhesive with cross-linked microphase separation structure. These findings indicate that mechanical ball milling can be employed to strip BN followed by combination with SPI, resulting in a tight bonded interface connection. Subsequently, the adhesive' s dry and wet shear strengths increased by 14.3% and 90.5% to 1.83 and 1.05 MPa, respectively. The resultant adhesive also possesses a good thermal conductivity (0.363 W/mK). Impressively, because hot-pressing helps the resultant adhesive to establish a thermal conduction pathway, the thermal conductivity of the resulting wood-based composite is 10 times higher than that of the SPI adhesive, which shows a thermal conductivity similar to that of ceramic tile and has excellent potential for developing biothermal conductivity materials, geothermal floors, and energy storage materials. Moreover, the adhesive possessed effective flame retardancy (limit oxygen index = 36.5%) and mildew resistance (>50 days). This bionic design represents an efficient technique for developing multifunctional biomass adhesives and composites.

In this study, SPI and BN were ball milled through the microphase separation structure of the biomimetic spider silk, and BN@SPI was obtained as a protein containing a crystalline structure and disordered structure. CPA, a yperbranched flame retardant synthesized under nucleophilic action, is introduced to BN@SPI and forms a tight structure under the interaction of TGA (a cross-linker), resulting in a strong, thermal conductive, and flame-retardant adhesive. The modified adhesive BN@SPI-CPA-TGA exhibited a 14.3% and 90.5% increase in dry and wet shear strength to 1.05 and 1.83 MPa, respectively, when compared to the adhesive SPI. CPA endows the adhesive with excellent flame-retardant performance, and the LOI of the BN@SPI-CPA-TGA adhesive is up to 36.5%, which is very important for preventing the fire hazards of wood-based panels. The modified adhesive also has good mildew resistance, which can reach at least 20 days. Notably, the presence of BN gives the SPI-based composite good thermal conductivity. The resultant adhesive also possesses a good thermal conductivity (0.363 W/mK) compared to the adhesive SPI. Impressively, the heat conduction path is formed by the hot-pressing orientation. Therefore, the heat conduction of the particleboard prepared with the BN@SPI-CPA-TGA adhesive (1.308 W/mK) is 10 times higher than that of the SPI adhesive, which can be applied to thermally conductive floors. The proposed strategy can offer a simple and efficient method for preparing high performance, multifunctional composites.

The first author of the paper is Zhang Xin, a doctoral student in the School of Materials Science, the corresponding authors are Professor Gao Qiang and Lecturer Li Jingchao from the wood adhesive team, and Beijing Forestry University is the signature unit of the first author.

This work was financially supported by the National Natural Science Foundation of China (642101016 & 32071702), the National Natural Science Foundation of China Youth Fund (no. 52103072), Beijing Natural Science Foundation (no. 2222068), and Beijing Forestry University Outstanding Young Talent Cultivation Project (2019JQ03004).

Paper link: https://doi.org/10.1021/acsnano.3c03782