Latest news

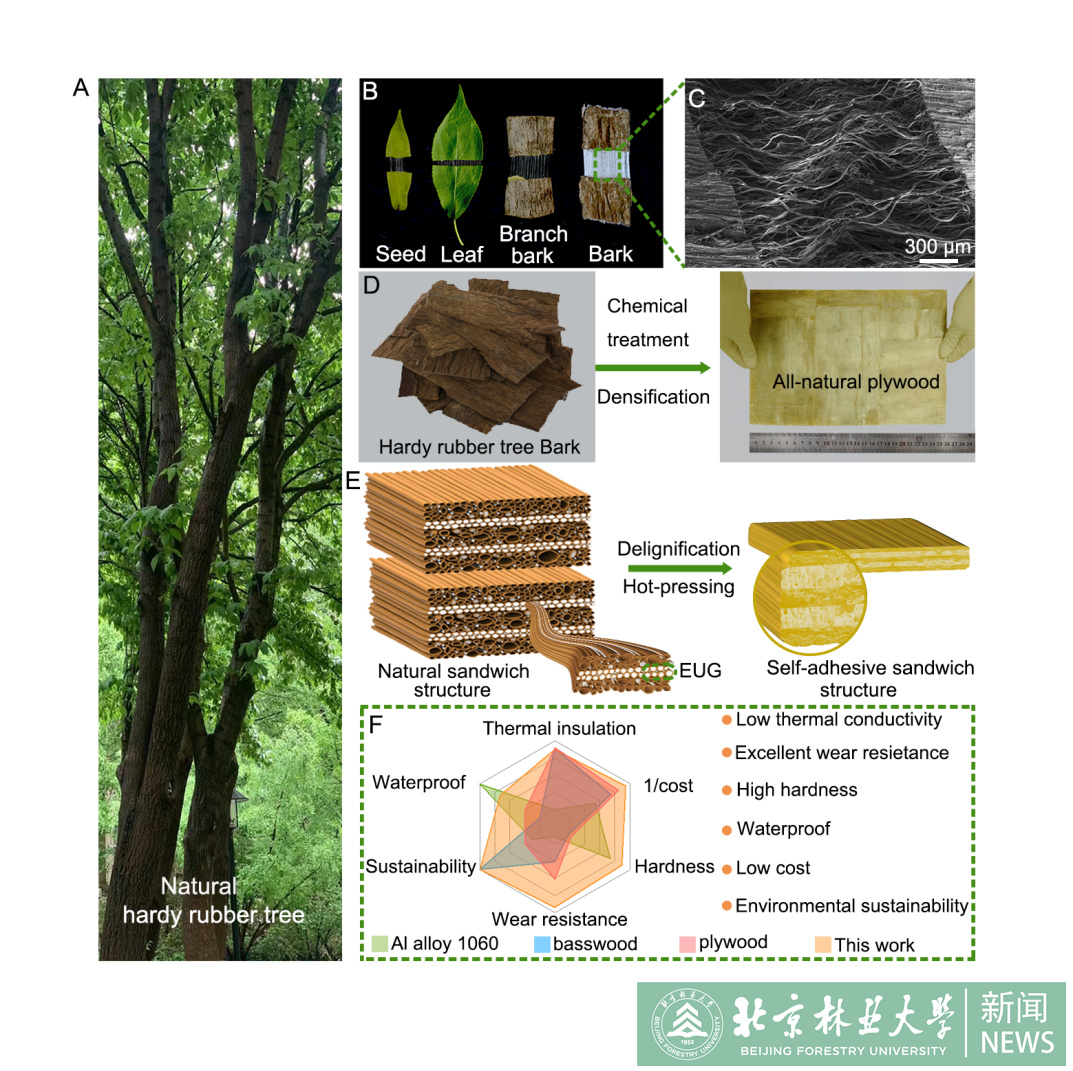

Recently, the research group led by Peng Feng from the College of Materials Science and Technology of Beijing Forestry University designed an all-natural, self-supporting, thermal insulating, and wear-resistant plywood made of self-adhesive bark veneer directly from HRT bark without any additional adhesives or polymers based on natural sandwich structure. The research result entitled "A self-adhesive bark veneer for all-natural plywood”was published in EcoMat(IF=14.6).

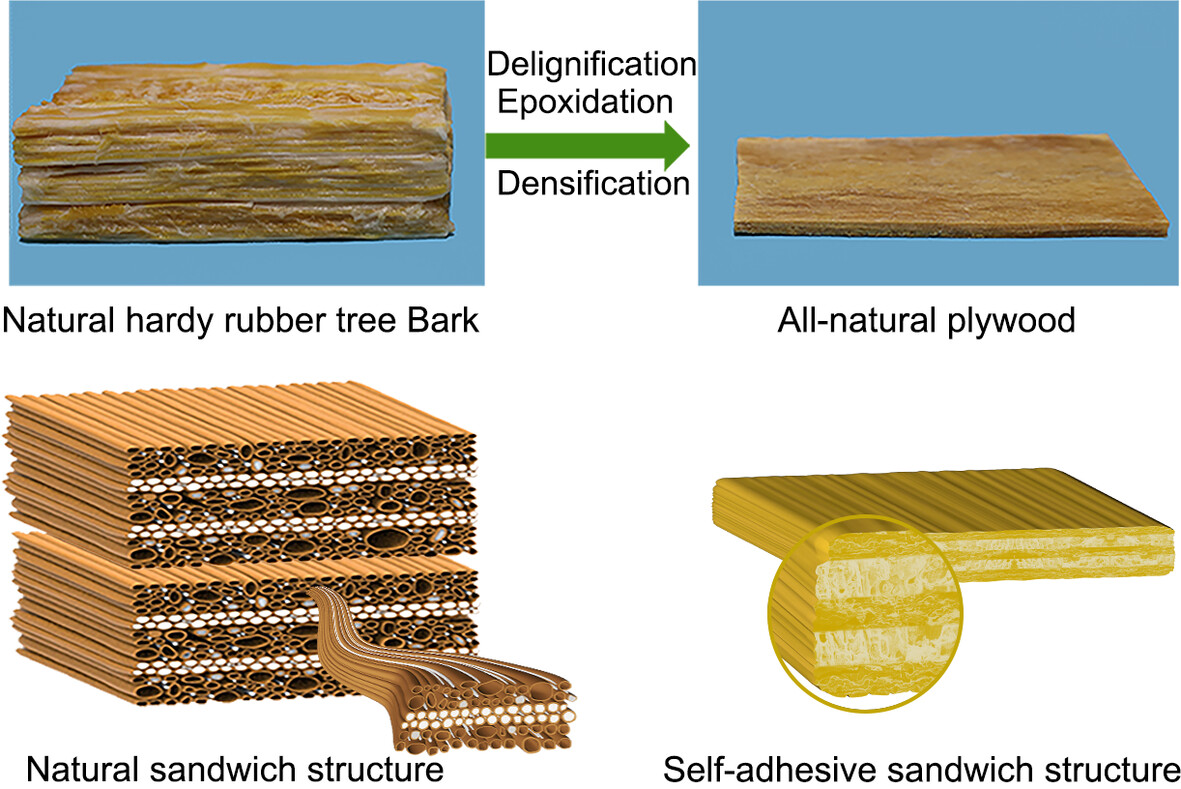

The commercial plywood is mainly made of high-value wood veneer and formaldehyde-based adhesives, which pose a major risk to human health and environmental protection. Here, we report an all-natural plywood made of self-adhesive bark veneer directly from hardy rubber trees (HRT) via delignification, epoxidation reaction and densification. The resulting bark veneer is demonstrated with sandwich structures featuring natural integration between cellulose and biopolymer Eucommia ulmoides gum (EUG). The intrinsic EUG act as a potential strong “self-adhesive” and water-proofing agent, leading to bark veneer with high hardness, excellent hydrophobicity, wear resistance, and low thermal conductivity. Furthermore, we can produce the self-adhesive plywood on a large scale directly from HRT bark using this approach without any adhesives, endowing it with environmental friendliness, safety in use, and health benefits of human beings. Combining its efficient and low-cost production, the bark veneer shows great promise in fabricating high-performance and environmentally sustainable plywood.

Wu Zhongxuan, graduate student of the College of Materials Science and Technology, is the first author of the paper, Associate Professor Chen Gegu and Professor Peng Feng are the co-corresponding authors, and the Beijing Key Laboratory of Lignocellulosic Chemistry of Beijing Forestry University is the first completed unit.

This research was financially supported by the National Natural Science Foundation of China (Grant No. 22208023), Beijing Nova Program (Z211100002121099; 20220484214), Fundamental Research Funds for the Central Universities (2021ZY21), China National Postdoctoral Program for Innovative Talents (BX20200061), National Science Foundation for Distinguished Young Scholars of China (32225034), and Ministry of Education, China-111 Project (BP0820033).

Paper link: https://doi.org/10.1002/eom2.12405