Latest news

Recently, the research team of bio-based adhesives of the School of Material Science and Technology from Beijing Forestry University has made new progress. The research result, entitled "A Strong Soy Protein based Adhesive with Excellent Water Retention," was published in Chemical Engineering Journal (IF=15.1) , the top journal of the Chinese Academy of Sciences in the field of engineering technology.

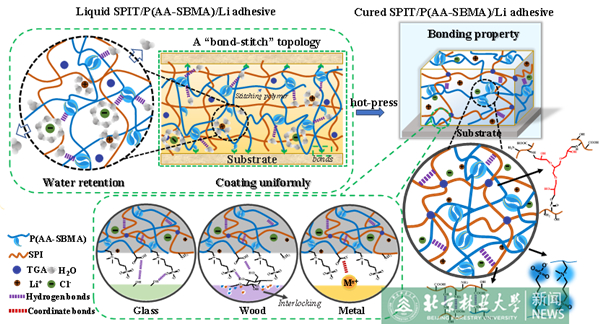

Traditional synthetic resin adhesives release harmful substances and can be replaced with more sustainable, eco-friendly, and healthier soy protein-based adhesives. However, the low water retention of these adhesives leads to an unstable bonding performance, which hampers their widespread application. Enhancing the water retention of the adhesive while maintaining its bonding and coating performance poses a significant challenge. In this work, a “bond-stitch” topology was designed and constructed by free radical copolymerization between acrylic acid and zwitterionic sulfobetaine methacrylate. This topology was combined with lithium chloride and a self-made epoxy crosslinking agent to construct a water-retaining and enhancing structure in soy protein adhesive systems, achieving simultaneous improvement in water retention, bonding strength, and coating performance. The adhesive exhibited an average shear strength of 1.77 MPa for wood and 1.82 MPa for stainless steel. Additionally, the coating performance was significantly improved, allowing uniform coating on wet poplar veneers (up to 120% moisture content) and low surface free energy substrates. Importantly, the adhesive allowing over 75% of the mass to remain after 24 h of storage in an open environment. This strong water-retaining and enhancing structure construction strategy offers a promising way to develop bio-based adhesives and hydrogels, promoting their widely application.

The first author of the research paper is Huang Xinxin, a doctoral student from the School of Material Science and Technology, and the corresponding author is Professor Gao Qiang of the State Key Laboratory of Efficient Production of Forest Resources, Key Laboratory of Wood Material Science and Application. Beijing Forestry University is the signature unit of the first author.

This work was financially supported by the National Natural Science Foundation of China (32071702 & 31722011) and Beijing Forestry University Outstanding Young Talent Cultivation Project (2019JQ03004).

Paper link: https://doi.org/10.1016/j.cej.2023.145037